How To Suppress Dust Through High Pressure

Do you know that PM10 dust in the unit is very harmful to most industries? A large amount of dust generated during transportation and manufacturing will seriously endanger the health of workers. Dust can cause serious health risks, such as respiratory diseases, if it spreads into the air without treatment. In addition, your industrial facilities may receive subpoenas and fines.

The following are methods of dust generation in various industries:

● Coal mining

Coal dust is the main cause of corrosion in all underground mines. This is produced by crushing coal. Coal reacts with air to form an oxidizing atmosphere, where iron(steel) oxidation occurs, resulting in rust of conveyor, gantry, chute and other structures.

● Construction industry

If dry powder sprayer is used to remove the paint of iron structure, high concentration of inhalable dust will be generated, including extremely harmful particles such as iron oxide(rust). These particles are easy to enter the lungs, causing silicosis, emphysema, bronchitis and other respiratory diseases. Lead smoke/dust is dangerous, and lead paint shall be removed mechanically before blasting.

● Cement industry

The cement industry produces harmful dust due to blasting, cutting, grinding, crushing, drilling and other activities. These activities may result in the emission of inhalable particles(less than 10 microns in diameter). It is reported that haze can lead to cancer, bronchitis, asthma and other complications. Because these particles(dust) will bypass the nose throat filter and go deep into the lungs, causing serious damage to human health. For these reasons, the cement industry should be far away from residential areas.

● Glass production

Carbon dioxide from glass manufacturing or glass processing is a by-product of silicosis. There is no cure for this respiratory disease. Because once they are injured by dust, they cannot recover. Protective masks shall be used for melting furnace, polishing and glass cutting.

● Stone cutting/grinding

Cutting or grinding stones can also release inhalable dust particles, which are dangerous. This is especially true when the stone contains crystal quartz(carbon dioxide). Respiratory dust exposure can lead to silicosis, which is untreatable. Because if it is damaged due to dust exposure, the lungs cannot recover. Wear masks when cutting or grinding stone.

● Wood industry

The wood industry inhales sawdust consisting of small particles(particles smaller than 10 mm in diameter) that easily penetrate the lungs and cause serious damage through nostril filters. The most common diseases associated with sawdust exposure include woodworking pneumoconiosis and asthma.

The best way to solve this problem and suppress the large amount of dust in industrial activities is to install a high-pressure spray system. First, let’s understand the scientific principle behind the high-pressure spray system.

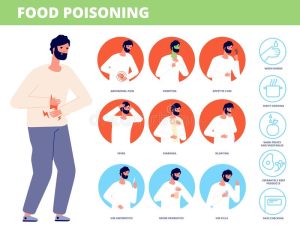

Working principle of spray system

The high-pressure host purifies the water and pressurizes it to more than 4-6 MPa. The water hits the special nozzle through the pipe, changing the velocity distribution of the jet section, so that the large particle liquid is broken and the fog becomes small particles. Under the action of aerodynamic force, particles are further materialized into countless “particles”. Fine fog “; diameter 10-20 mm.”; fine fog “; floats in the air, absorbs dust in the air, transforms water from liquid to gas, and increases humidity in the air.

Configuration of spray system

- Main components:

● High voltage host

● Special dust suppression nozzle

● Spraying parts: including nozzle support, elbow, tee joint, straight joint, valve, etc.

● Pipe: 304 or 316 stainless steel

- Other parts:

● Filtering system: three-stage filtering or stainless steel filtering

● Dosing device: adding chemicals

● Water tank: store a large amount of water

Atomizing parts(1) Atomizing parts(2)

Advantages of spray system

The atomization system has become a reliable dust suppression method. Advantages include:

● Easy to use

The droplet size used is approximately 10 to 20 mm(10 to 20 thousandths of an inch). This is smaller than most other technologies. For example, if water is sprayed or sprayed, the dust may rise into the air again. As a result, you can save on labor costs. Different from the traditional method, two people must monitor the work site while manually operating each nozzle, so they can work without adding more people.

● Security

The water used in the spray system is safe for people and the environment. The size of the droplets is very small, which means that there is less water splashing from the workers’ bodies or nearby buildings. Compared with common methods such as cutting or strong cleaning, it is not irritating to the eyes. The staff will not be exposed to chlorine bleach, ammonia, hydrochloric acid, boron minerals and other toxic substances related to dust suppression with water, so there is no health problem.

● Durability and efficiency

The spray system is designed to work for several years compared to the mechanical drive system, thus reducing maintenance costs. The fog system is most effective because it can cover 100000 square feet on flat terrain. The fog nozzle is also very durable, made of stainless steel, with ball joints for easy maintenance.

● Effectiveness

It is proved that using spray system to control dust can achieve the effect that other methods cannot effectively achieve. It can inhibit dust while providing a conducive working environment. It can be seen that after the fog melts, the visible dust in all areas covered by the fog will be reduced. Depending on the waiting conditions, it may be completed within minutes or hours after implementation.

● Low water consumption

The atomization system is designed to provide optimum pressure over the entire height range. It can control 500-4000 square meters of spreading space. According to the regional requirements, the water flow can be adjusted between 100-1600 kg/h as required. Considering the flow of conventional atomizing nozzle, the water consumption per hour is only 2.5L/H.

● Low maintenance cost

The installed spray system requires little maintenance. On average, the components of the fog system are much less than most other types of dust suppression devices. Some spreaders may be required, so there are no nets, hoses or parts to maintain.

● Reduce operating costs

The working efficiency of the atomization system is higher than that of other methods(such as water, lime, etc.). The fog from our fog nozzle contains small water droplets and will not wet or damage the equipment, tools or other objects in the fog area. This enables tasks without delay.

● Unlimited working range

Almost all spray systems can be used indoors or outdoors, depending on the type of project. Provides speed and flexibility with little impact on the work schedule.

● Provide results immediately

For other types of inhibition, you must wait for 24 hours until the working environment becomes clean again, but the spray system will produce obvious effects in less than an hour.

● No residue

Other types of dust suppressants will leave residues, making it difficult for equipment and machines to work properly. This is because residues are generally composed of harmful chemicals, which penetrate into the equipment, resulting in slow function and even electrical failure.

Application of spray System in Industry

The following is information on how to apply spray system to suppress dust in various industries.

● Metal production

Metal dust particles contain harmful chemicals that may pollute the environment. If dust is not properly controlled or eradicated, it will bring health problems to workers. The ventilation and filtration system alone cannot remove all aerosol metals from the working environment. After the implementation of the project, the metal must be kept moist to prevent the air from polluting the room, liquid storage tank and conduit again.

In addition to this protection function, the wet surface is also covered with oxide compounds formed by water electrolysis, which can better resist corrosion. The positive and negative poles of the same material can be placed in parallel. Water mist covers the surface to protect it from atmospheric oxygen corrosion.

● Daylighting

Mining workers and the environment have adverse health effects. Exposure to harmful substances such as arsenic, nickel, lead, zinc and even uranium will affect health. The spray system can prevent alkaline dust(such as sodium compounds) from reacting with water to produce alkaline lakes. In addition, some metal dust may contain metals that can be fatal in contact with water.

● Powder production

In addition to operations in metal production, the spray system also plays an important role in maintaining the health of workers by removing harmful chemical particles from the air breathed by workers. In addition to this function, some powders can react with the moisture in the atmosphere to generate explosive compounds such as nitride or carbonate, so it is necessary to protect the environment.

● Cement production

Fog helps to separate dust before entering the fan to collect fine particles. The spray system can also help cement producers to reduce the dust emission of cooked materials during the cement grinding process and reduce environmental pollution. Another advantage is to reduce the risk of inhalation of toxic solid gas in the process of grinding and packaging, and improve the safety of workers.

● Phosphate manufacturing

Spray is helpful for dust separation, oxidation and subsequent filtration, avoiding the subsequent problems of phosphate products. Improper use will damage the growth of crops or animals.

The process of installing the spray system is not easy, and it takes a long time to install everything correctly, which is very challenging. The best choice is to be guided by experienced experts. It is recommended that you find a spray company with many years of installation experience. Nebufly has been established for more than 10 years and provides first-class services to customers. We can quickly and effectively build a complete spray system for all personal or commercial spaces. Please feel free to contact us via email or phone.